This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

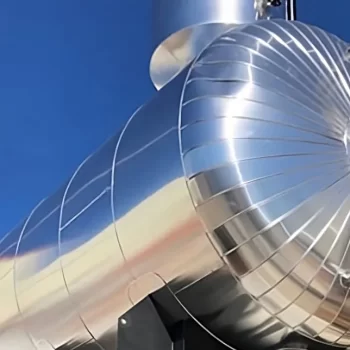

Instman Field IFDG Model – Thermal Degasser

The degassing system that we make in our facilities allows us to eliminate those gases that by their nature are not condensable and at the same time are very corrosive and that are present in the feed water of the steam generators, such as oxygen or carbon dioxide.

The equipment is mainly made up of two notable parts: the upper container, where the process of eliminating gases dissolved in the liquid takes place; the lower container, the space where the degassed water accumulates after having elapsed and descended through the previous container.

CHARACTERISTICS

Elimination of oxygen and non-condensable gases found in the boiler feed water.

Corrosion of elements that make up the boiler and therefore the sections that make up the water-steam circuit of the associated installation is avoided, a phenomenon is known as “pitting”. Extension of the useful life of the equipment.

Economic savings in the chemical treatment applied to the boiler supply water by reducing the necessary chemical agents, since after the degassing process, the amount to be dissolved will be reduced.

Economic savings due to energy losses in the purges, since the periodicity of action may be reduced.

Compliance with Directive 2014/68/UE and design according to UNE-EN 13445 as pressure vessels not subjected to flame.

AISI 304 or AISI 316L stainless steel construction in areas containing O2.

Maximum service pressure 0.5 bar.

Maximum service temperature 110°C.

It has a manhole for registration and maintenance.

It has the necessary connections for its installation and respective control elements.